Precision Manufacturing Solutions

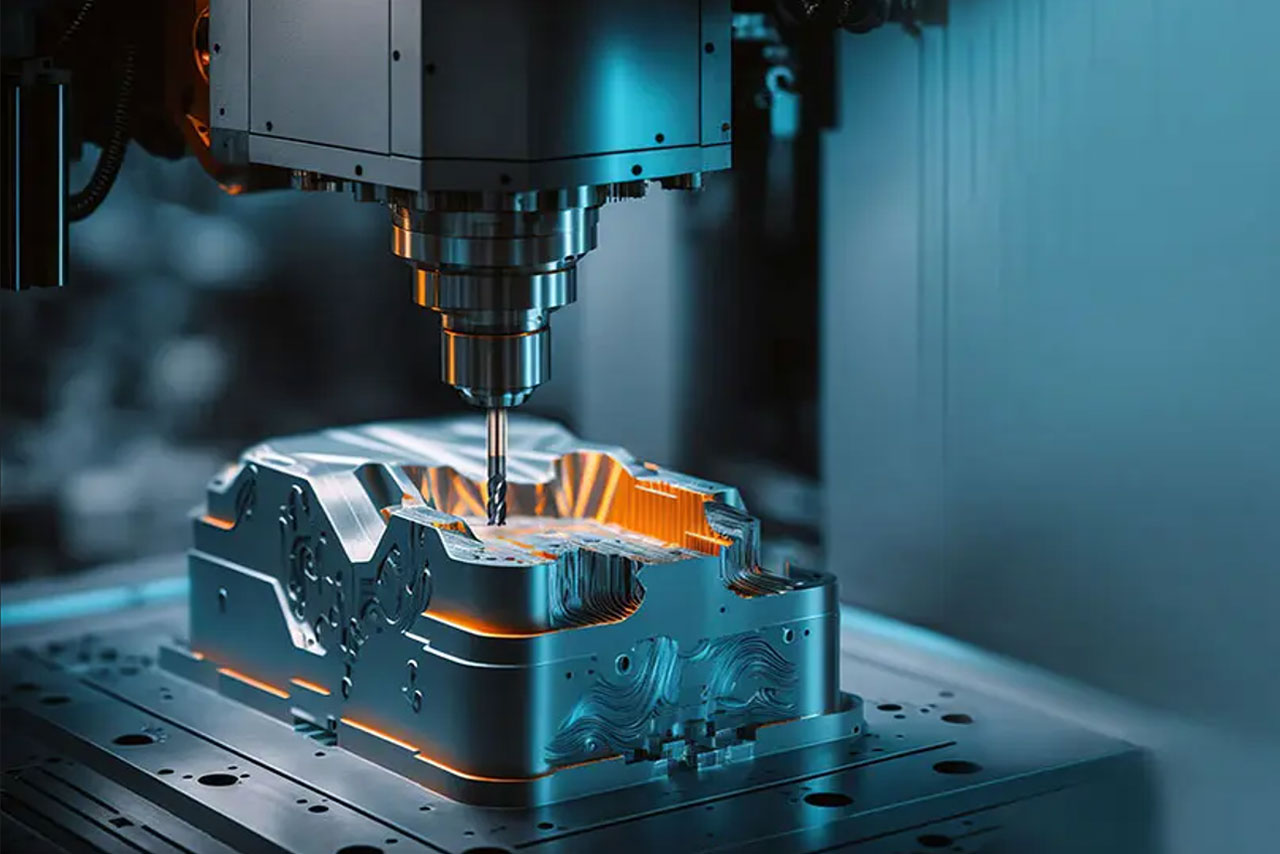

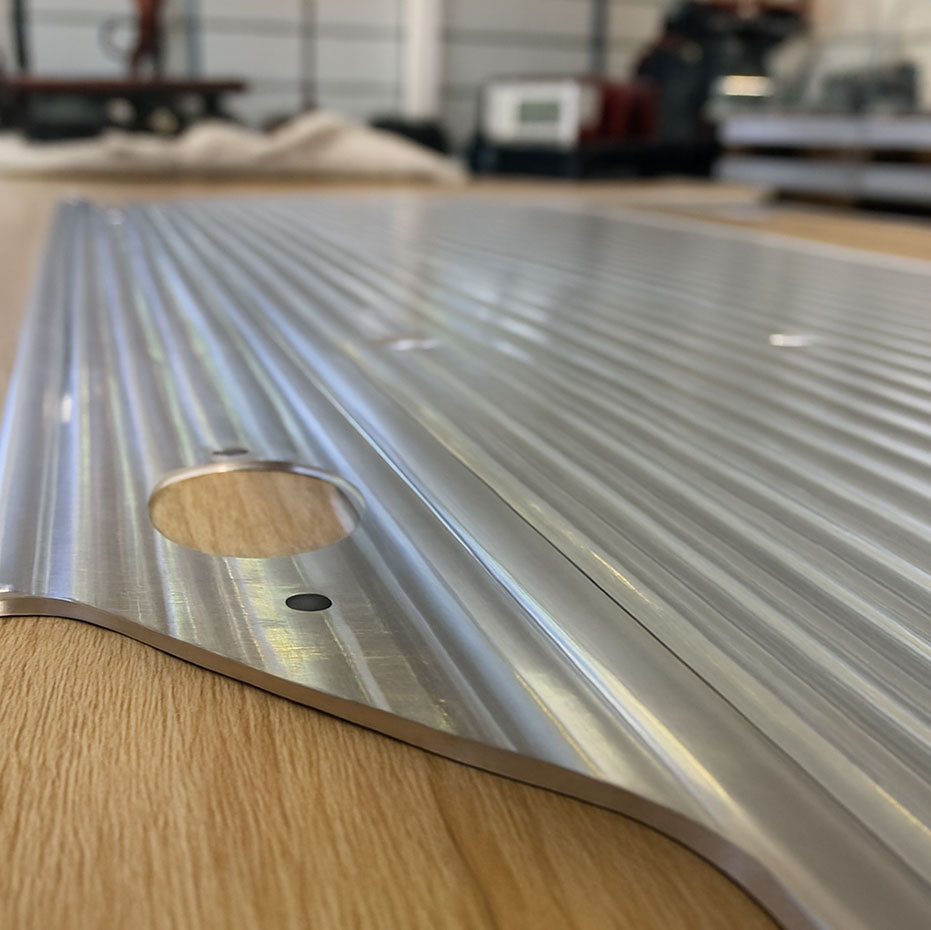

As Profix Engineering, we specialize in manufacturing components that require high precision, dimensional accuracy, and excellent surface quality in industrial production processes. Our large-scale Awea LP3025 machining center, equipped with 3+2 axis capability and a rotary head attachment, provides an advanced solution for machining complex geometries.

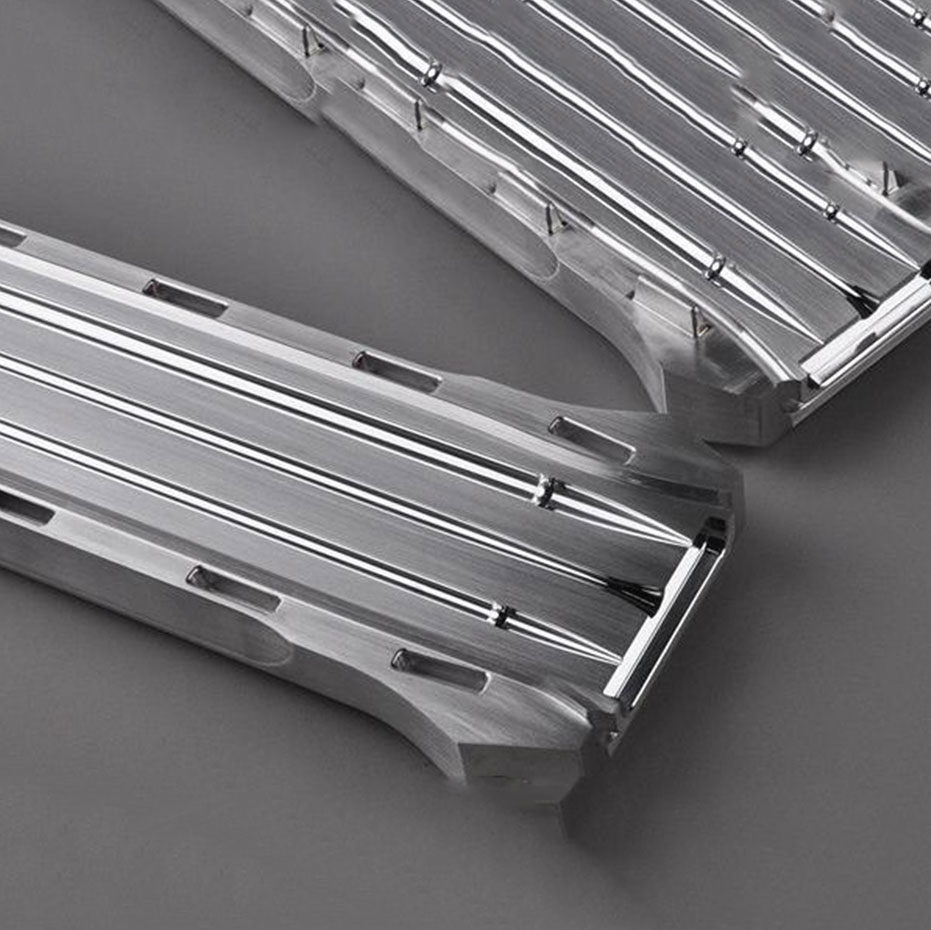

In particular, we play a critical role in projects for the aerospace and defense industries, where the precise machining of high-strength materials such as Aluminum 7075 / 6082 and titanium alloys is essential.

The machining of functional components such as complex fasteners, structural support parts, and adapter blocks is carried out on our systems operating with tight tolerances. All production processes are completed with CMM-based quality control and compliance verification according to customer specifications.

We offer extensive manufacturing flexibility ranging from prototype production to low-volume batch manufacturing. Our services include engineering-supported CAD/CAM modeling, toolpath optimization, and material selection, allowing us to deliver not only components but also tailored engineering solutions to meet our clients’ technical needs.

Copyrights © 2025 ProFix Engineering Ind. Trade Inc. All Rights Reserved.

Kayapa / BURSA